Lintlha tse Potlakileng

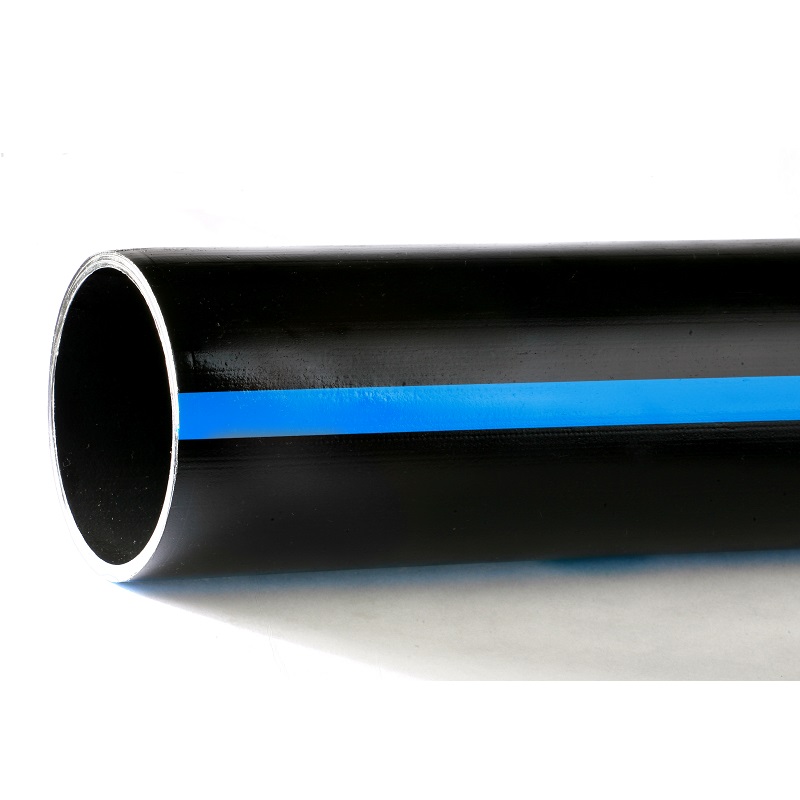

Lethathamo la lintlha: EI042502KK

Boima ka lebitso: 12mm-110mm

Khatello ea tekanyo: 0.25Mpa, 0.4Mpa, 0.6Mpa

Suit able: Lipeipi tsa nosetso tse mahareng le tse phahameng tse sebelisoang bakeng sa likarolo tse ka tlas'a lefatše tsa

liphaephe tse kholo tse kang ho nosetsa lipeipi, nosetso ea micro-sprinkler;liphaephe tsa ho nosetsa tse nang le khatello e tlase li ka

Ho sebelisoa liphaephe tsa makala tsa nosetso ea lipeipi, ho nosetsa ka metsi, ho nosetsa ka marotholi.

Mocheso o sebetsang: 0-45 ℃

Mokhoa oa khokahanyo: E hokahane haholo le khokahano e potlakileng.

Dayu Water Saving Group Co., Ltd. e thehiloe ka 1999. Ke khoebo ea naha ea theknoloji e phahameng e thehiloeng ho Setsi sa Machaena sa Mahlale a Metsi, Setsi sa Phatlalatso ea Saense le Theknoloji sa Lekala la Mehloli ea Metsi, Sekolo sa Mahlale sa China, Sekolo sa Machaena sa Boenjiniere le litsi tse ling tsa lipatlisiso tsa mahlale.E thathamisitsoe 'marakeng oa Growth Enterprise.Stock Code: 300021. Khampani e thehiloe ka lilemo tse 20 'me e' nile ea tsepamisa maikutlo le ho inehela ho tharollo le tšebeletso ea temo, libaka tsa mahaeng le mehloli ea metsi.E fetohile pokello ea ho baballa metsi a temo, phepelo ea metsi litoropong le mahaeng, tlhoekiso ea likhoerekhoere, litaba tsa metsi a bohlale, khokahanyo ea tsamaiso ea metsi, taolo ea tikoloho ea metsi le tokiso le mafapha a mang.Mofani oa tharollo ea tsamaiso ea setsebi bakeng sa ketane eohle ea indasteri e kopanyang moralo oa morero, moralo, matsete, kaho, ts'ebetso, tsamaiso le litšebeletso tsa tlhokomelo.Ke indasteri ea pele lefapheng la ho boloka metsi a temo naheng ea China hape e le moetapele oa lefats'e.

Polyethylene e phahameng haholo, lebitso la Senyesemane ke "High Density Polyethylene", kapa "HDPE" ka bokhutšoanyane.HDPE ke resin e khanyang haholo, e seng polar thermoplastic resin.Ponahalo ea HDPE ea pele e tšoeu ea lebese, 'me karolo e tšesaane e fetoha ho isa bohōleng bo itseng.PE e na le khanyetso e ntle ho lik'hemik'hale tse ngata tsa malapeng le tsa indasteri.Mefuta e meng ea lik'hemik'hale e ka baka kutu ea lik'hemik'hale, joalo ka li-oxidants tse corrosive (concentrated nitric acid), li-hydrocarbon tse nkhang hamonate (xylene) le li-halogenated hydrocarbons (carbon tetrachloride).Polymer ha e na hygroscopic ebile e na le khanyetso e ntle ea mouoane oa metsi, 'me e ka sebelisoa molemong oa ho paka.HDPE e na le lisebelisoa tse ntle tsa motlakase, haholo-holo matla a phahameng a dielectric a ho kenya letsoho, a etsa hore e tšoanelehe haholo bakeng sa lithapo le likhoele.Limaraka tse mahareng ho isa ho tse phahameng tsa boima ba limolek'hule li na le ts'ebetso e ntle haholo ea ho hanyetsa, esita le mocheso oa kamore esita le mocheso o tlase oa -40F.

HDPE ke thermoplastic polyolefin e hlahisoang ke copolymerization ea ethylene.Leha HDPE e ile ea thakholoa ka 1956, polasetiki ena ha e so fihle boemong bo holileng.Thepa ena ea sepheo se akaretsang e lula e ntlafatsa ts'ebeliso ea eona e ncha le limmaraka.

Lintlha tse ka sehloohong

HDPE ke resin e seng polar thermoplastic e nang le kristale e phahameng.Ponahalo ea HDPE ea pele e tšoeu ea lebese, 'me karolo e tšesaane e fetoha ho isa bohōleng bo itseng.PE e na le khanyetso e ntle ho lik'hemik'hale tse ngata tsa malapeng le tsa indasteri.Mefuta e meng ea lik'hemik'hale e ka baka kutu ea lik'hemik'hale, joalo ka li-oxidants tse corrosive (concentrated nitric acid), li-hydrocarbon tse nkhang hamonate (xylene) le li-halogenated hydrocarbons (carbon tetrachloride).Polymer ha e na hygroscopic ebile e na le khanyetso e ntle ea mouoane oa metsi, 'me e ka sebelisoa molemong oa ho paka.HDPE e na le lisebelisoa tse ntle tsa motlakase, haholo-holo matla a phahameng a dielectric a ho kenya letsoho, a etsa hore e tšoanelehe haholo bakeng sa lithapo le likhoele.Limaraka tse mahareng ho isa ho tse phahameng tsa boima ba limolek'hule li na le ts'ebetso e ntle haholo ea ho hanyetsa, esita le mocheso oa kamore esita le mocheso o tlase oa -40F.Litšobotsi tse ikhethang tsa limaraka tse fapaneng tsa HDPE ke motsoako o nepahetseng oa mefuta e mene ea mantlha: letsoalo, boima ba limolek'hule, kabo ea boima ba limolek'hule le li-additives.Li-catalyst tse fapaneng li sebelisoa ho hlahisa li-polymer tse ikhethileng tse nang le thepa e ikhethang.Motsoako oa mefuta ena o hlahisa limaraka tsa HDPE bakeng sa merero e fapaneng;ho fihlella tekanyo e ntle ka ho fetisisa tshebetsong.

tekano

Ena ke eona phapang e ka sehloohong e khethollang litšobotsi tsa HDPE, leha mefuta e mene e boletsoeng e ama e mong.Ethylene ke ntho e ka sehloohong e tala ea polyethylene.Li-comonomers tse ling tse seng kae, tse kang 1-butene, 1-hexene kapa 1-octene, le tsona hangata li sebelisoa ho ntlafatsa tshebetso ea polymer.Bakeng sa HDPE, litaba tsa li-monomers tse ka holimo hangata ha li fete 1% -2%.Ho eketsoa ha comonomer hanyenyane ho fokotsa crystallinity ea polymer.Phetoho ena ka kakaretso e lekanyetsoa ka ho teteana, e nang le kamano e lekanang le crystallinity.Sehlopha se akaretsang sa United States se lumellana le ASTM D1248, 'me boima ba HDPE ke 0.940g/.Ka holimo ho C;Tekanyo ea boholo ba MDPE ke 0.926 ~ 0.940g/CC.Likarolo tse ling ka linako tse ling li beha MDPE joalo ka HDPE kapa LLDPE.Li-homopolymers li na le sekhahla se phahameng ka ho fetisisa, ho satalla ka ho fetesisa, ho kenella hantle le sebaka se phahameng ka ho fetisisa sa ho qhibiliha, empa ka kakaretso li na le khanyetso e mpe ho ho phatloha ha khatello ea tikoloho (ESCR).ESCR ke bokhoni ba PE ho hanela ho phatloha ho bakoang ke khatello ea mochine kapa lik'hemik'hale.Boima bo phahameng ka kakaretso bo ntlafatsa matla a mochine, joalo ka matla a tsitsitseng, ho satalla le ho thatafala;thepa ea mocheso e kang ho nolofatsa ntlha mocheso le mocheso khopameng mocheso;le ho se kenelle, joalo ka ho kenella ha moea kapa ho kenella ha mouoane oa metsi.Boima bo tlase bo ntlafatsa matla a eona a tšusumetso le E-SCR.Boima ba polymer bo angoa haholo ke ho eketsoa ha li-comonomers, empa ho isa tekanyong e nyane ke boima ba limolek'hule.Liphesente tse phahameng tsa boima ba limolek'hule li fokotsa ho teteana hanyenyane.Ka mohlala, li-homopolymers li na le li- density tse sa tšoaneng mefuteng e mengata ea boima ba limolek'hule.

Ho hlahisa le ho kenya letsoho

Mokhoa o tloaelehileng oa tlhahiso ea PE ke ka ts'ebetso ea slurry kapa khase ea khase, 'me tse' maloa li hlahisoa ke ho sebetsa ha karolo ea tharollo.Ts'ebetso tsena kaofela ke karabelo e makatsang e kenyelletsang ethylene monomer, a-olefin monomer, catalyst system (e kanna ea ba motsoako o fetang o le mong) le mefuta e fapaneng ea li-diluent tsa hydrocarbon.Hydrogen le li-catalysts tse ling li sebelisoa ho laola boima ba limolek'hule.The slurry reactor ka kakaretso ke tanka e tsukutloang kapa mochini o sebelisoang hangata o moholo oa loop moo slurry e ka tsamaisoang le ho tsukutleha.Ha ethylene le comonomer (joalokaha ho hlokahala) li kopana le catalyst, likaroloana tsa polyethylene li thehoa.Kamora ho tlosa mokelikeli, li-polyethylene granules kapa li-powder granules li omisitsoe 'me li-additives li kenngoa ho ea ka tekanyo ea ho hlahisa li-pellets.Mohala oa sejoale-joale oa tlhahiso o nang le li-reactor tse kholo tse nang le li-scruder tse mafahla o ka hlahisa liponto tse fetang 40,000 tsa PE ka hora.Nts'etsopele ea li-catalyst tse ncha e kenya letsoho ho ntlafatseng ts'ebetso ea limaraka tse ncha tsa HDPE.Mefuta e 'meli e sebelisoang haholo ea li-catalysts ke li-catalysts tse thehiloeng ho chromium oxide tsa Philips le li-catalyst tsa titanium compound-alkyl aluminium.HDPE e hlahisoang ke Phillips catalyst e na le kabo ea boima ba limolek'hule ka bophara;titanium-alkyl aluminium catalyst e na le kabo e moqotetsane ea boima ba limolek'hule.Sehlahisoa se sebelisoang tlhahisong ea lipolymer tse moqotetsane tsa MDW ka har'a reactor e habeli le tsona li ka sebelisoa ho hlahisa limaraka tse pharalletseng tsa MDW.Ka mohlala, li-reactor tse peli tse latellanang tse hlahisang lihlahisoa tsa boima ba limolek'hule tse fapaneng haholo li ka hlahisa li-polymer tsa boima ba limolek'hule tsa bimodal tse nang le mefuta e mengata ea boima ba limolek'hule.Lisebelisoa tsa lipeipi tsa PE

Boima ba molek'hule

Boima ba limolek'hule bo phahameng bo fella ka viscosity e phahameng ea polymer, empa viscosity e boetse e amana le mocheso le sekhahla sa ho kuta se sebelisitsoeng tekong.Rheology kapa tekanyo ea boima ba limolek'hule e sebelisoa ho khetholla boima ba limolek'hule tsa thepa.Likereiti tsa HDPE ka kakaretso li na le mefuta e fapaneng ea boima ba limolek'hule ho tloha ho 40 000 ho isa ho 300 000, 'me boima bo tloaelehileng ba boima ba limolek'hule bo batla bo lumellana le mefuta ea melt index, ke hore, ho tloha ho 100 ho ea ho 0. 029/10min.Ka kakaretso, MW e phahameng (low melt index MI) e matlafatsa matla a ho qhibiliha, ho tiea ho betere le ESCR, empa MW e phahameng e etsa ts'ebetso.

Ts'ebetso e thata haholo kapa e hloka khatello e phahameng kapa mocheso.

Kabo ea boima ba limolek'hule (MWD): WD ea PE e fapana ho tloha ho e moqotetsane ho ea ho bophara ho itšetlehile ka mokhoa o sebelisoang le mokhoa oa ho sebetsa.

Molaetsa o sebelisoang ka ho fetisisa oa MWD ke index ea unevenness (HI), e lekanang le boima bo tloaelehileng ba boima ba limolek'hule (MW) e arotsoe ka palo karolelano ea boima ba limolek'hule (Mn).Lenane lena la index bakeng sa limaraka tsohle tsa HDPE ke 4-30.MWD e moqotetsane e fana ka warpage e tlaase le tšusumetso e phahameng nakong ea ho bopa.MWD e mahareng ho isa ho bophara e fana ka ts'ebetso bakeng sa lits'ebetso tse ngata tsa extrusion.Wide MWD e ka boela ea ntlafatsa matla a ho qhibiliha le khanyetso ea creep.

tlatsetso

Ho eketsoa ha li-antioxidants ho ka thibela ho senyeha ha polymer nakong ea ts'ebetso le ho thibela oxidation ea sehlahisoa se felileng nakong ea ts'ebeliso.Li-additives tsa antistatic li sebelisoa lihlopheng tse ngata tsa ho paka ho fokotsa ho khomarela ha libotlolo kapa liphutheloana ho lerōle le litšila.Lisebelisoa tse khethehileng li hloka li-additive formulations, joalo ka li-copper inhibitors tse amanang le terata le lisebelisoa tsa cable.Ho hanyetsa boemo ba leholimo bo botle le ho thibela mahlaseli a kotsi (kapa khanya ea letsatsi) ho ka finyelloa ka ho eketsa li-additives tse khahlanong le UV.Ntle le ho eketsoa ha UV-resistant kapa carbon black PE, ho khothalletsoa hore u se ke ua tsoela pele ho e sebelisa ka ntle.Li-pigments tsa carbon black tsa boemo bo holimo li fana ka khanyetso e ntle ea UV 'me hangata li sebelisoa lits'ebetsong tsa kantle, joalo ka lithapo, lithapo, mekato ea litanka kapa liphaephe.

mekhoa ea ho sebetsa

PE e ka etsoa ka mekhoa e mengata e fapaneng ea ts'ebetso.Ho sebelisa ethylene e le eona ntho e ka sehloohong e tala, propylene, 1-butene, le hexene e le copolymer, tlas'a ts'ebetso ea "catalyst", "slurry polymerization" kapa "gas phase polymerization process" e amoheloa, 'me polymer e fumanoeng ea benya, e arotsoe, e omisitsoe, e omisitsoe. , joalo-joalo Mokhoa oa ho fumana lihlahisoa tse felileng ka likaroloana tse tšoanang.Ho kenyelletsa joalo ka lakane extrusion, filimi extrusion, pipe kapa profil extrusion, blow molding, ente molding le rotational molding.

▲Extrusion: Mokhahlelo o sebelisoang bakeng sa tlhahiso ea extrusion ka kakaretso o na le index ea ho qhibiliha e ka tlase ho 1 le MWD e bohareng ho isa ho bophara.Nakong ea ts'ebetso, MI e tlase e ka fumana matla a loketseng a ho qhibiliha.Limaraka tse pharalletseng tsa MWD li loketse ho feta bakeng sa extrusion hobane li na le lebelo le phahameng la tlhahiso, likhatello tse tlase tsa lefu le tšekamelo e fokotsehileng ea ho robeha ha ho qhibiliha.

PE e na le lisebelisoa tse ngata tsa extrusion, tse kang lithapo, lithapo, liphaephe, liphaephe le profiles.Lisebelisoa tsa lipeipi li qala ho tloha liphaepheng tse tšehla tse nyenyane bakeng sa khase ea tlhaho ho ea ho lipeipi tse ntšo tse nang le marako a teteaneng tse bophara ba 48in bakeng sa lipeipi tsa indasteri le tsa litoropo.Tšebeliso ea liphaephe tse sekoti tse bophara ba bophara bo boholo e le sebaka sa lipeipi tsa metsi a pula tse entsoeng ka konkreite le lipeipi tse ling tsa likhoerekhoere e ntse e hōla ka potlako.

Sheet le thermoforming: Lesela la thermoforming la lihatsetsi tse ngata tse kholo tsa pikiniki li entsoe ka PE, e thata, e bobebe ebile e tšoarella.Lihlahisoa tse ling tsa lakane le thermoformed li kenyelletsa balebeli ba seretse, litšepe tsa litanka, balebeli ba lipane, mabokose a likepe le litanka.Palo e kholo ea likopo tsa maqephe tse ntseng li hola ka potlako ke metsaneng e ka tlase ea mulch kapa ea matangoana, e thehiloeng holim'a ho tiea, ho hanyetsa lik'hemik'hale le ho se mele ha MDPE.

▲Blow molding: Ho feta 1/3 ea HDPE e rekisoang United States e sebelisetsoa ho bōptjoa ha molumo.Tsena li tloha ho libotlolo tse nang le bleach, oli ea motor, sesepa, lebese le metsi a hloekisitsoeng ho ea ho lihatsetsi tse kholo, litanka tsa mafura a koloi le likoti.Litšobotsi tsa limaraka tsa ho bopa, joalo ka matla a qhibilihang, ES-CR le ho tiea, li ts'oana le tse sebelisoang bakeng sa lits'ebetso tsa sheet le thermoforming, kahoo limaraka tse tšoanang li ka sebelisoa.

Ho bopeha ka ente hangata ho sebelisoa ho etsa lijana tse nyane (ka tlase ho 16oz) bakeng sa ho paka meriana, li-shampoo le litlolo.E 'ngoe ea melemo ea ts'ebetso ena ke hore libotlolo tsa tlhahiso li hloekisoa ka mokhoa o itekanetseng, ntle le tlhokahalo ea mehato ea ho qetela ka mor'a ho qeta joaloka ho bopa ka kakaretso.Le hoja limaraka tse ling tse tšesaane tsa MWD li sebelisoa ho ntlafatsa bokaholimo, limaraka tsa MWD tse mahareng ho isa ho tse pharalletseng hangata lia sebelisoa.

▲ Ho bopa ka ente: HDPE e na le lits'ebetso tse se nang palo, ho tloha ho linoelo tsa lino tse tšesaane tse ka sebelisoang hape ho isa ho makotikoti a 5-gsl, a jang 1/5 ea HDPE ea lapeng.Limaraka tsa ho bopa ente hangata li na le index ea ho qhibiliha ea 5-10.Ho na le limaraka tse nang le boima ba 'mele le maemo a tlase a metsi le limaraka tse holimo tse nang le ts'ebetso.Tšebeliso e kenyeletsa litlhoko tsa letsatsi le letsatsi le lijo tse nang le marako a tšesaane;lijo tse thata le tse tšoarellang le makotikoti a pente;khanyetso e phahameng ea lits'ebetso tse senyang khatello ea tikoloho, joalo ka litanka tse nyane tsa mafura a enjene le makotikoti a litšila a 90-gal.

▲ Ho bopa ho potolohang: Lisebelisoa tse sebelisang mokhoa ona oa ho sebetsa hangata li siloa hore e be lisebelisoa tsa phofo, tse qhibilihang ebe li phalla ka potoloho ea mocheso.Rotomolding e sebelisa mefuta e 'meli ea PE: sepheo se akaretsang le se kopanyang.Kakaretso ea MDPE / HDPE hangata e na le boima bo tlohang ho 0.935 ho ea ho 0.945g / CC, e nang le MWD e moqotetsane, e le hore sehlahisoa se be le tšusumetso e phahameng le warpage e fokolang, 'me index ea eona ea ho qhibiliha hangata e le 3-8.Limaraka tse phahameng tsa MI ka kakaretso ha li tšoanelehe hobane ha li na tšusumetso le khatello ea tikoloho e lebelletsoeng ho hanyetsa lihlahisoa tse entsoeng ka rotomold.

Lisebelisoa tsa ho bopa tse sebetsang hantle haholo li sebelisa litšobotsi tse ikhethang tsa limaraka tsa eona tse amanang le lik'hemik'hale.Limaraka tsena li na le mokelikeli o motle karolong ea pele ea potoloho ea ho bopa, 'me ka mor'a moo li kopana ho theha khanyetso e ntle ea khatello ea tikoloho le ho tiea.Apara ho hanyetsa le ho hanyetsa boemo ba leholimo.Cross-linkable PE e loketse feela lijana tse kholo, ho tloha ho litanka tsa 500-gal bakeng sa ho tsamaisa lik'hemik'hale tse fapaneng ho isa litanka tsa temo tsa 20,000-gal.

▲Filimi: Ts'ebetso ea filimi ea PE hangata e sebelisa ts'ebetso e tloaelehileng ea filimi kapa ts'ebetso ea extrusion e bataletseng.Boholo ba PE bo sebelisoa bakeng sa filimi, PE (LDPE) ka kakaretso ea low-density kapa linear low-density PE (LLDPE) e fumaneha.Limaraka tsa lifilimi tsa HDPE hangata li sebelisoa moo ho hlokahalang ho otlolla ho hoholo le ho se khonehe ho hoholo.Ka mohlala, filimi ea HDPE e atisa ho sebelisoa bakeng sa mekotla ea thepa, mekotla ea korosari le ho paka lijo.

Ts'ebetso ea sehlahisoa

Polyethylene e phahameng haholo ha e na chefo, ha e latsoehe, ebile ha e na monko o mosoeu ka ntlha ea ho qhibiliha hoo e ka bang 130°C le boima bo lekanyelitsoeng ba 0.941 ho isa ho 0.960.E na le ho hanyetsa mocheso o motle le ho hanyetsa serame, botsitso bo botle ba lik'hemik'hale, bo tiileng bo phahameng le ho tiea, le matla a matle a mochine.Thepa ea dielectric le khatello ea khatello ea tikoloho e hanyetsanang le eona e ntle.

Ho paka le ho boloka

Qoba hole le mollo le mocheso nakong ea polokelo.Sebaka sa polokelo se lokela ho bolokoa se omme ebile se le makhethe.Ho thibetsoe ka thata ho kopanya litšila leha e le life, khanya ea letsatsi le pula.Lipalangoang li lokela ho bolokoa ka likariking tse hloekileng, tse omeletseng, tse koahetsoeng, 'me ho se be le lintho tse bohale tse kang lipekere tsa tšepe.Lipalangoang tse tsoakiloeng tse nang le li-hydrocarbon tse nkhang hamonate, li-halogenated hydrocarbons le lihlapolli tse ling tsa tlhaho li thibetsoe ka thata.

botjha le ho sebedisa hape

HDPE ke karolo e holang ka potlako ea 'maraka oa polasetiki.Sena se bakoa haholo-holo ka lebaka la ho ntlafala habonolo, litšobotsi tse fokolang tsa ho senyeha le palo e kholo ea likopo bakeng sa ho paka.Ntho e ka sehloohong ea ho sebelisoa hape ke ho lokisa 25% ea lisebelisoa tse sebelisoang hape, tse kang post-consumer recyclables (PCR), ka HDPE e hloekileng ho etsa libotlolo tse sa kopane le lijo.

Liphaephe tsa PE bakeng sa phepelo ea metsi ke lihlahisoa tse nkelang sebaka sa lipeipi tsa tšepe tsa setso le lipeipi tsa metsi a nooang tsa PVC.